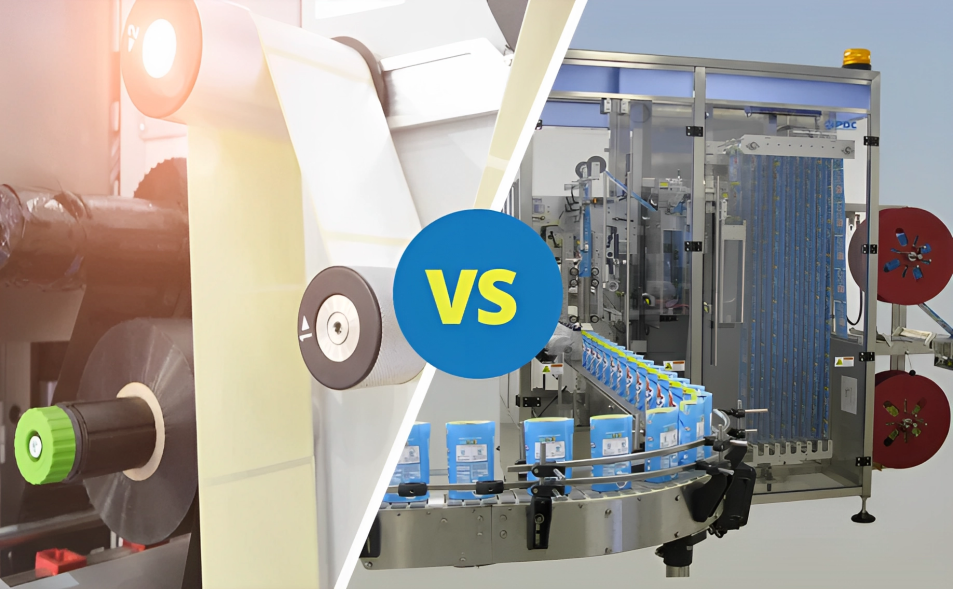

Exploring The Differences Between Shrink Sleeve Labels And Pressure-Sensitive Labels

Labels are an extremely important component of product packaging, as they are responsible for attracting in customers and providing them with crucial information regarding the product. Shrink sleeve labels and pressure-sensitive labelling are two popular choices among the many available labelling methods. Both have their own distinct benefits and can satisfy a variety of packaging requirements. As a means of assisting you in making an educated decision regarding the packaging of your product, we will examine the distinctions that exist between these two approaches to labelling in this blog.

Shrink Sleeve Labels

Shrink sleeve labels, also called shrink wrap labels, are a special kind of packaging label that completely covers what is inside. Heat-shrinkable plastics like PVC, PETG, and OPS are commonly used for the printing of these labels. After being wrapped around the container, the label is heated to cause it to shrink and take on the exact shape of the package, giving it a polished and professional appearance.

Shrink Sleeve Labels Benefits

- 360-Degree Design: Labels applied to containers using shrink sleeves can feature complex, eye-catching designs that wrap completely around the package. This opens up more possibilities for advertising, helping products stand out on store shelves.

- Tamper-Proof: Shrink sleeves with a tamper-evident seal provide an extra layer of security for products by showing customers that their purchases are unopened and safe.

- compatibility with Various Container Shapes: Shrink sleeve labels are adaptable for a wide variety of packaging applications due to their compatibility with a wide variety of container shapes and sizes.

- Moisture and Abrasion Resistance: Durable and resistant to moisture and abrasion, shrink sleeve labels will keep their form and visual appeal throughout shipping and storage.

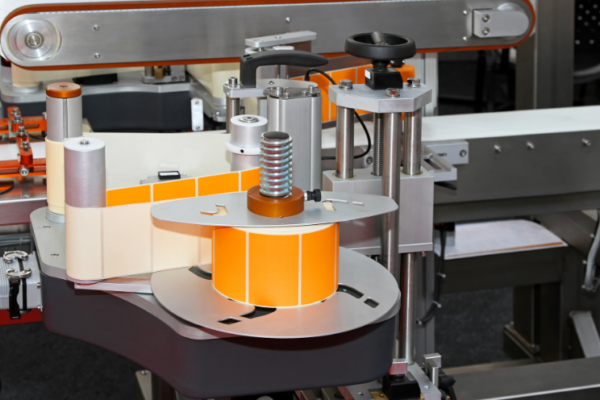

Pressure-Sensitive Labeling

Pressure-sensitive labels adhere to flat surfaces commonly used for labelling containers by applying pressure to the label’s adhesive backing. These labels typically come with a release liner protecting the adhesive backing and are printed on paper, film, or foil. Applying pressure causes the label to stick firmly to the container.

Pressure-sensitive Labels Benefits

- Ease of Use: There is no need for heat or specialised equipment when using pressure-sensitive labels. The label can be applied to the container either by hand or with a machine that applies labels.

- Versatility: Pressure-sensitive labels are adaptable because they can be placed on a variety of container types, including glass, plastic, metal, and more. To accommodate a wide range of aesthetic preferences, they come in a number of different finishes, including matte, glossy, and textured.

- Cost-Effective: Pressure-sensitive labels are more cost-effective than other labelling methods because they don’t need special machinery or heat-shrink film for application.

- Instant Adhesion: Pressure-sensitive labels stick instantly and securely to the surface of the container, remaining in place for the duration of the product’s shelf life.

How to Determine Which Labelling Strategy Is Best for Your Product?

Consider your product’s requirements and branding preferences when deciding between pressure-sensitive labels and shrink-sleeve labels from the best label manufacturer in India. Shrink sleeve labels may be the best option if you need designs that can be seen from all angles, tamper-proofing, and flexibility concerning the shape of the container. However, pressure-sensitive labelling may be preferable if you place a premium on factors like convenience, adaptability, economy, and instant adhesion.

Suggested Reads: EVERYTHING YOU NEED TO KNOW ABOUT IML LABELS

In conclusion, both pressure-sensitive labelling and shrink-sleeve labels are useful and meet various needs in terms of packaging. The decision will depend on the type of product you’re selling, your branding goals, and your available funds.

When you work with S. Anand Packaging reliable label manufacturer in India, you can find a label design that complements your product’s aesthetics and increases its marketability.