Keeping tabs on every item moving through your supply chain is crucial. That’s where track and trace labels come into play. This label system does more than just mark packages—they’re essential tools for a smooth and efficient operation. These labels are necessary for growing manufacturers who are committed to quality. Successful businesses use these labels to stay on top of production, from the factory floor to final delivery, ensuring every product meets high standards. In this blog, we’ll explore how track and trace labels help businesses maintain quality and attract new customers, even in uncertain market conditions.

Know Where Your Stuff Is – Always

Track and trace labels let you watch your products from the warehouse to the customer’s doorstep. Imagine being able to see where everything is at any given moment. This isn’t just convenient; it’s a game changer. For instance, if there’s a delay, you’ll know about it instantly and can manage the situation before it escalates.

Less Loss, More Profit

When you use these labels, your chances of losing products drop drastically. Each item has its unique identifier, making mix-ups and misplacements rare. This means fewer losses and more accurate deliveries. And what does this translate to? Yes, better profits and happier customers.

Speed Things Up

With track and trace labels, checking in products as they arrive and leave becomes a breeze—no more manual counts or guesswork. Everything is scanned and automatically logged. This speeds up processing times, reduces errors, and keeps your operations running smoothly. Imagine the relief of not having to worry about manual counts or guesswork and the ease of having everything automatically logged.

Keep Your Customers Happy

By leveraging supply chain track and trace labels, businesses can offer customers timely updates on their orders, empowering them with precise delivery timelines. This improves the overall customer experience and fosters satisfaction with the service provided.

How to Get Started

If you’re thinking, “This sounds great, but how do I get started?” here are some tips to find the best label manufacturer. Choosing the proper label manufacturer in India is crucial because they can provide high-quality, customisable labels that fit your needs. Here’s what to consider:

- Quality and Durability: Ensure the labels withstand different environments without fading or peeling off.

- Customisation: Can the manufacturer tailor the labels to your specifications? This includes size, information, and adhesive quality.

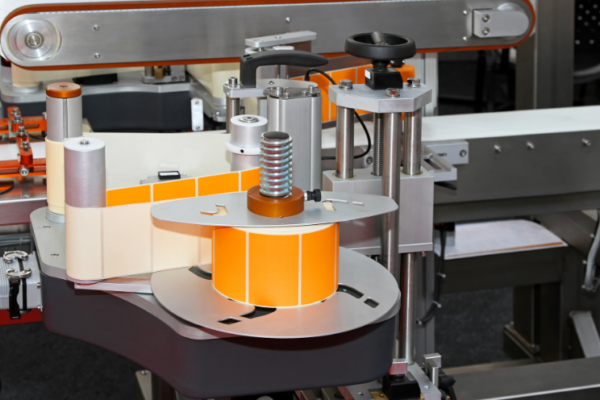

- Technology: Opt for labels compatible with modern tracking systems using barcodes or RFID technology.

Suggested Reads –WHAT ARE DURABLE LABELS AND THEIR COMMON APPLICATIONS?

Conclusion

Using track and trace labels is like having a magic crystal ball for your supply chain. They let you see everything in real-time, keep your goods safe, and speed up your operations, all while keeping your customers informed and happy. When choosing a label manufacturer, experience and expertise matter, and S. Anand Packaging is one of the leading label manufacturers in India. We have provided high-quality, customisable track and trace labels for many years. We can manufacture labels according to international printing standards such as GMI. Additionally, we are audited to be a socially responsible employer by globally recognised standards published by SEDEX. Contact us if you’re ready to take your supply chain to the next level.

Remember, it’s not just about tracking; it’s about delivering confidently and precisely.