When it comes to packaging, the choice between digital and conventional printing methods can significantly impact the outcome of your product’s presentation. In the highly competitive world of consumer goods, labels like battery labels play an important role in not just providing information but also in creating a visual appeal. In this blog, we will explore the two primary packaging methods and highlight their benefits to help you decide which is right for your business.

Conventional Printing Method

Conventional printing, also known as offset printing, has been a staple in the packaging industry for decades. This method involves transferring ink from a plate to a rubber blanket before it is finally applied to the printing surface, typically paper or cardboard. One of the key advantages of conventional printing is its ability to handle large-scale production runs efficiently. The setup costs are higher than digital printing, but the per-unit cost decreases as the volume increases.

Conventional printing provides a wide array of colour options, ensuring vibrant and consistent results. This makes it an ideal choice for brands that require precise colour matching and a high level of detail. Additionally, conventional printing allows for the use of unique inks and finishes, such as metallic or spot varnishes, further enhancing the visual appeal of the packaging.

However, it’s essential to note that conventional printing has its limitations. The turnaround time can be longer compared to digital label printing in Noida, which might not align with the fast-paced demands of some industries.

Digital Printing Method

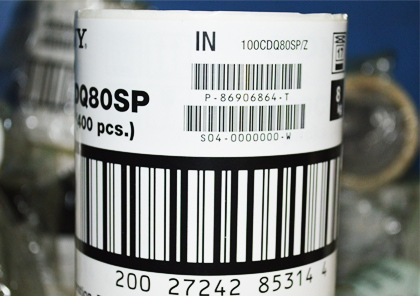

In contrast, digital printing has emerged as a game-changer in packaging. This method uses digital technology to transfer the design directly onto the substrate without needing plates or cylinders. For battery labels, digital printing offers unmatched flexibility and quick turnaround times. It allows for variable data printing, enabling businesses to personalize each label with unique information, serial numbers, or graphics.

One notable advantage of digital printing is the ability to produce small to medium-sized batches cost-effectively. This makes it an ideal choice for businesses that require frequent design changes, seasonal variations, or limited edition runs. Moreover, digital printing eliminates the need for extensive setup, making it a more environmentally friendly option with reduced waste.

Which is Right for Your Business?

Choosing between digital and conventional printing ultimately depends on your business’s specific needs and priorities. If your products require large quantities with intricate designs and unique finishes, conventional printing may be the preferred route. On the other hand, if you value flexibility, cost-effectiveness for smaller runs, and the ability to personalize your packaging, digital printing could be the optimal solution.

Suggested Reads: WHAT ARE DURABLE LABELS AND THEIR COMMON APPLICATIONS?

Conclusion

Understanding the strengths and limitations of each printing method is crucial for making an informed decision. Assess your packaging requirements, production volumes, and budget constraints to determine whether the traditional precision of conventional printing or the modern adaptability of digital printing aligns better with your business goals. If you are looking for the best digital label printing in Noida, S.Anand Packaging offers you top-notch labels at convenient pricing. Our commitment to excellence and relentless pursuit of quality has positioned us as a trusted partner for businesses seeking top-tier digital label printing solutions. Our team of skilled professionals takes pride in staying ahead of industry trends and delivering results that exceed expectations. So what are you waiting for? Visit our website today and get high-quality packaging in your budget!