In just seven seconds, consumers form a quick impression of a product based on its label alone. These fleeting moments can determine whether a product ends up in the shopping cart or stays on the shelf. Product labelling holds immense importance as it’s the first thing consumers glance at before making a purchase. Psychology tells us that consumers are driven by emotions when buying, and an appealing, long-lasting label triggers positive feelings. This emotional connection increases the likelihood of a purchase.

In-mould labelling (IML) is one such widely used packaging method where labels are applied directly onto containers during manufacturing, streamlining the process. But what exactly is in-mould labelling, and why is it becoming so popular? Let’s dive in and explore everything there is to know about this innovative packaging solution from a top IML label manufacturer, S. Anand Packaging.

What Is IML?

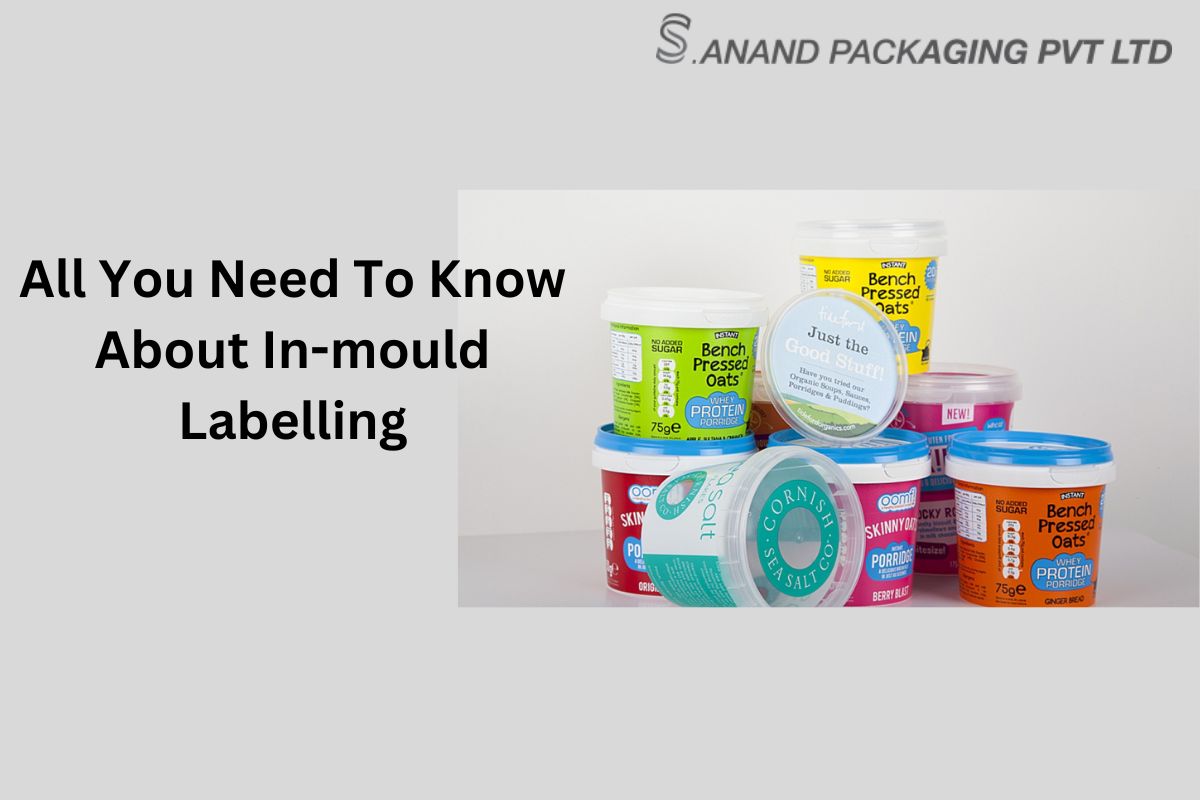

IML is a technique where labels are placed directly into the mould while plastic containers are manufactured. Instead of sticking labels afterwards, they become an integral part of the product.

How Does It Work?

- Injection Molding: First, the plastic container is created using injection moulding. The molten plastic flows into the mould, taking the shape of your favourite food container or shampoo bottle.

- Label Placement: Before the mould closes, a pre-printed label is inserted. The label adheres to the plastic as it cools down. Voila! Your container now has a permanent label.

- One-Step Process: IML combines two steps—moulding and labelling—into one. It’s like multitasking for plastic!

Diverse Methods of In-Mould Labelling

In-molud labelling (IML) can be achieved through various processes, with injection moulding, thermoforming, and blow moulding being the most common methods.

- Injection Molding: This process involves the IML label manufacturer placing a label in the mould using a polymer carrier and securing it with mechanical means or air pressure. Molten plastic is later on injected into the mould, fusing with the label to create a permanent decoration on the plastic part. Injection IML is cost-effective and suitable for various products like ice cream tubs and computer keyboards.

- Blow Molding: In this method, plastic is heated until it forms a tube, which is then placed in the mould and blown to take the mould cavity’s shape. The label is fixed in the mould cavity before the plastic tube is placed, and as the tube is blown, the label fuses with the plastic to create durable products.

- Thermoforming: This process involves heating plastic sheets until they become soft, then stretching and placing them on the mould using vacuum suction or mechanical pressing. The plastic conforms to the mould’s shape and, after trimming, results in high-quality decorated plastic products. Though less common, thermoforming is effective for creating various products with intricate designs.

Why Choose IML?

- Enhanced Branding and Customisation: IML label manufacturer offers extensive branding options with high-quality colour printing and quick design changeovers, allowing manufacturers to create visually appealing labels tailored to their brand image.

- Versatility and Adaptability: IML’s flexibility allows for adaptation to various materials, designs, shapes, and sizes, meeting diverse industry needs and offering extensive customisation options.

- Counterfeit Prevention: By permanently fusing labels with products during moulding, IML provides a secure labelling solution that is difficult to replicate, safeguarding brand reputation and preventing financial losses due to counterfeit products.

Suggested Reads: WHAT ARE DURABLE LABELS AND THEIR COMMON APPLICATIONS?

Conclusion

In conclusion, understanding the impact of labelling on consumer decisions underscores the significance of in-mould labelling (IML) in packaging. Its efficiency and ability to create visually appealing, durable labels make it a valuable asset for brands seeking to captivate consumers. For top-notch packaging solutions leveraging IML, look no further than S. Anand Packaging. Elevate your product presentation and enhance consumer engagement with our expertise in IML or QR code labels. Contact us today to explore the possibilities!